Flow Chemistry vs Batch Chemistry: Choosing the Right Technique for Your Pharmaceutical Reactions

When it comes to organic chemistry reactions and pharmaceutical production, the one-size-fits-all approach doesn't apply. With flexibility being key to achieving efficiency and accuracy, we must examine the two primary contenders: flow chemistry and batch chemistry.

Understanding the Players: Flow and Batch Chemistry

Flow chemistry and batch chemistry are not polar opposites but extensions of one approach: efficient chemical transformation. Both techniques have their unique advantages, but their application is contingent on the intricacies of the pharmaceutical reaction in question. A sprinter wouldn't wear a scuba suit for a race, just like every chemical reaction has a preferred method of execution. Let's dig into these chemical terrains to find out which one would be better suited for your specific needs.

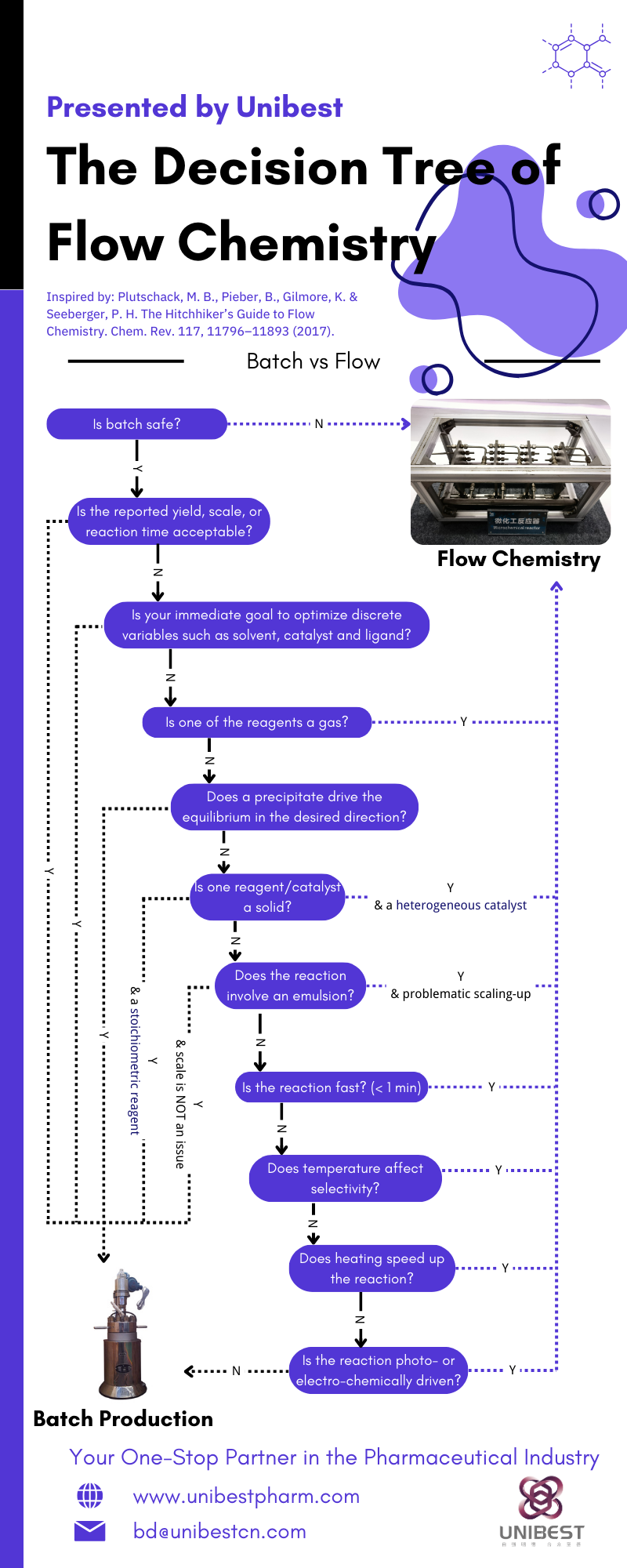

Safety First: Mitigating Potential Hazards

The safety of the chemist is paramount. For hazardous materials, heat exchange, and pressurized reactions, flow conditions nullify or at least alleviate the risks. The use of chip reactors in flow chemistry allows chemists to handle minimal quantities of hazardous materials, thereby reducing exposure. Moreover, matters like spills caused by human error can be largely eliminated by built-in quenches. The efficient heat exchange provided by the small dimensions of the flow reactors is also conducive to high-pressure conditions, reducing runaway reactions and extreme conditions.

Aligning Techniques with Project Goals

Each reaction purpose is unique and the chosen technique should align with its particular requirements. For reactions already established in batch, a chemist needs to question whether those conditions meet the project’s needs. If it’s effective, why fix it? Similarly, some discovery scale procedures may struggle when scaling to preparative phases. Therefore, immediate project goals should also come into the equation. For instance, while it is more convenient to screen variables (especially for discrete varibles such as solvent, catalyst, and ligand) in batch, for reactions with scarce starting materials, using small volume chip reactors in flow can be more efficient.

Multiphasic Systems: Gases and Solids

In reactions where a reagent is a gas, flow chemistry typically overtakes batch reactions due to lower headspace to solvent ratios and enhanced gas solubility in solution under pressure. For reactions involving solids, the situation becomes more nuanced. Batch reactions are preferred when the reaction completion is driven by precipitation or where reactants are insoluble in the reaction medium. However, for reactions involving heterogeneous catalysts, flow chemistry wins the round, as packed beds simulate high catalyst loadings reducing reaction times and performing well under triphasic conditions.

Emulsion, Rate and Selectivity Considerations

Flow chemistry shines in creating highly reproducible homogenous emulsions, essential in producing droplets and particles with narrower size distributions. In terms of reaction rates and selectivity, rapid reactions benefit from the enhanced mixing and better heat transfer in flow operation, improving yield. Flow reactors also boast a narrower temperature profile, reducing or eliminating energy-close side reactions. For slow-reaction compounds, flow-driven intensification of reaction conditions proves beneficial.

Light and Electricity: The Power Boosters

Reactions driven by photochemical or electrochemical means significantly benefit from flow conditions. The small dimensions of the flow reactor enable uniform irradiation, and the ability to carry out reactions without supporting electrolytes simplifies purification while potentially reducing cost.

So, what's the verdict? Flow or batch? It's all gray and no black and white – the decision requires careful analysis of safety considerations, scale needs, reagent availability, temperature controls, environment policies and potential challenges. Understanding your “chemical soup” and ultimate goals is the key to choosing the right path.

And remember, sometimes the well-tread path may not always be the most effective. At Unibest, our focus is on assisting our partners to make the best, informed decisions when it comes to pharmaceutical development and manufacturing. Need a hand navigating this complex landscape? Get in touch with our flow chemistry expert panel today to see how we can better optimize your processes with our innovative green chemistry solutions. Let’s maximize value together.